Self Drilling Screw Wafer Head

Self Drilling Screw Wafer Head

Material:Carbon Steel SAE1022

Head Type:Phillips Wafer

Coating Process:25µm Ruspert Coating

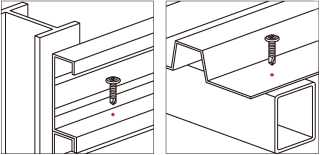

Application:Standing seam roof support,gypsum board and keel,windows and others.

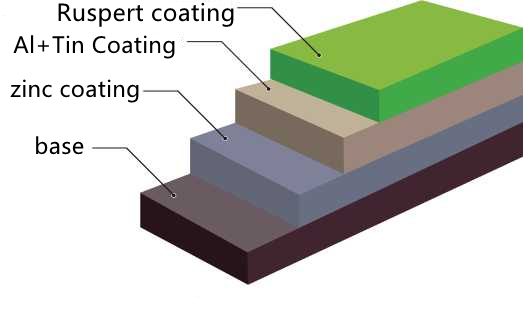

Ruspert Coating:Zinc-Tin Alloy Coating

Coating Process:Making Excellent Adhesion of Mechanical Coating

HardwareJet mechanical galvanized screws coating is produced according to Australia Standard for self-drilling screw corrosion resistant requirement AS-3566.2-2002 with metallurgical profile micro-density grade 8 require-ments, to ensure excellent coating adhesion. Firstly, the screws are coated by using a 360 degree rotation plating process to mechanically weld zinc and tin ally powder to the surface. This process helps zine plating coat evenly onto screw threads which helps to form the first layer of protection from corrosion. Screws are then soaked in liquid Ruspert and heated for solidification which form a second layer coating that could generates lubrication during drilling application and help reduce friction that could destruction the inner protection layer of zinc plating.Process under room temperature eliminates the re-tempering or softening. NON-Exposion to acid during production prevents screw from hydrogen embrittlement.

Adapter to Use:Phillips No 2 Cross Recess Bit